Xact Metal XM 200G Metal 3D Printer

Product Details:

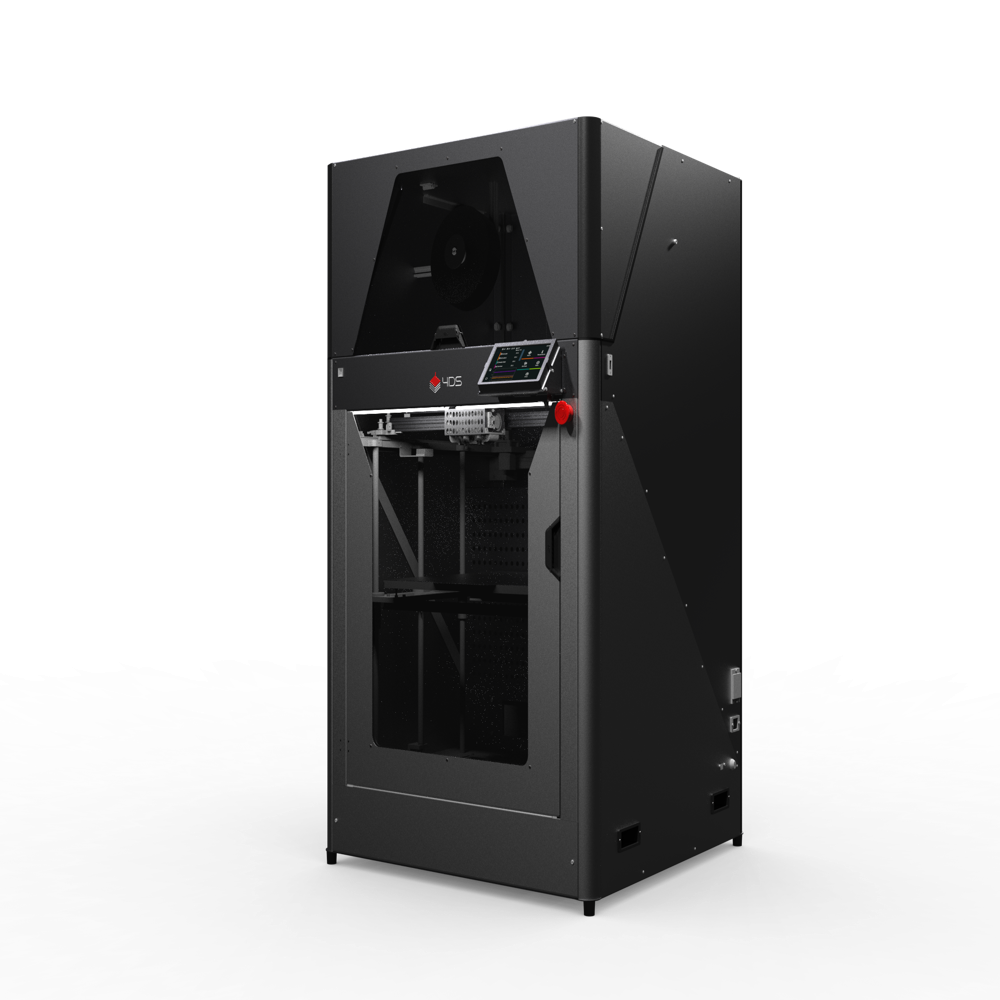

- Dimension (L*W*H) 650 x 780 x 1930 Millimeter (mm)

- Printer Type Selective laser Melting

- Printing Speed Jog Speed Up to 20.7 m/sec (Standard galvo), 34.6 m/sec (Performance galvo) m/s

- Nozzle Diameter laser spot size approximately 50 m or 100 m

- Voltage 230V Volt (v)

- Application Aerospace components, automotive parts, medical and dental implants, tooling and fixtures, R&D prototypes, small-batch manufacturing, and industrial metal components.

- Product Type 3D Printer

- Click to View more

Xact Metal XM 200G Metal 3D Printer Price And Quantity

- 32500000.0 INR/Number

- 1 Number

Xact Metal XM 200G Metal 3D Printer Product Specifications

- Selective laser Melting

- 650 x 780 x 1930 Millimeter (mm)

- Jog Speed Up to 20.7 m/sec (Standard galvo), 34.6 m/sec (Performance galvo) m/s

- laser spot size approximately 50 m or 100 m

- 3D Printer

- Aerospace components, automotive parts, medical and dental implants, tooling and fixtures, R&D prototypes, small-batch manufacturing, and industrial metal components.

- 230V Volt (v)

- DMLS

- LAN

- 1 Yr

- 150*150*150mm

- precision metal parts, rapid prototyping, tooling, jigs and fixtures, R&D, small batch production, and complex high-density components for aerospace, automotive, medical, and industrial applications.

- Single/dual 100 400 W fiber lasers with overlapping work areas, large 150 150 150 mm build volume, high speed galvanometer, premium F theta optics (50 100 m), integrated powder handling and optional glovebox, open material/parameter platform, small footprint, and modern software for precision high quality metal printing.

- Digital

- 380 Kilograms (kg)

- New

- upto 10 mm/sec

- Aluminum Si10M, Bronze, Copper (C18150), Stainless Steel: 316L, 17-4 PH, 15-5, 400, Super Alloys: 718, 625, Cobalt Chrome F75, Hastelloy X; Titanium Ti64; Tooling Steels: Maraging M300

Xact Metal XM 200G Metal 3D Printer Trade Information

- 6 Week

Product Description

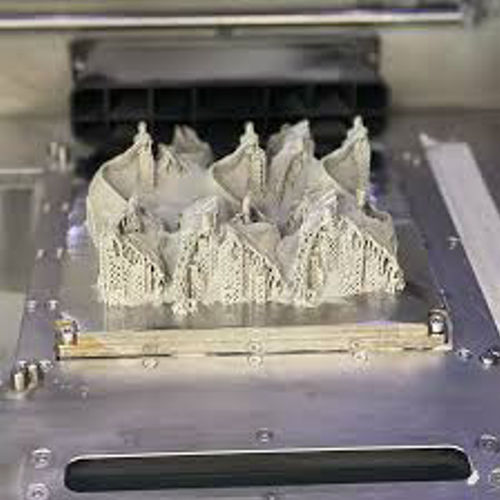

The Xact Metal XM200G is a metal powder-bed fusion 3D printer that offers a balance of industrial performance and affordability, aimed at small-to-medium manufacturers, R&D labs, universities, and advanced prototyping facilities. Its part of Xact Metals industrial lineup and builds on the companys proven metal AM technology.

It uses fiber laser(s) to selectively melt metal powder in a controlled environment, producing dense near-fully dense metal parts with complex geometries that are difficult or impossible with traditional manufacturing.

Features

-

Integrated powder handling system (improves safety and workflow).

-

Optional glovebox for safer powder changing/handling.

-

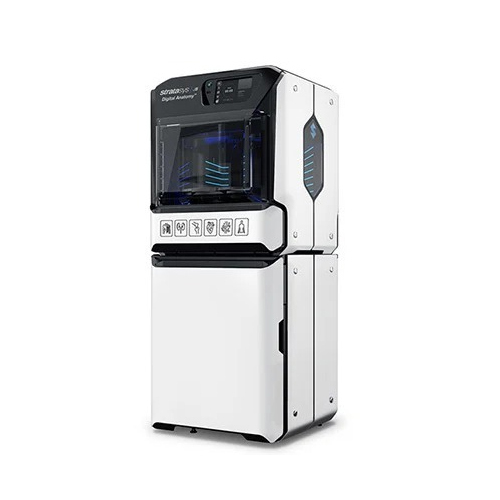

User-friendly touchscreen and modern software interface.

-

Open material platform and open print parameters for tuning and experimentation. l

Benefits of XM200G (Pointwise)

-

Balanced Industrial Performance: Offers high-quality LPBF printing at a more accessible price point compared with traditional industrial systems.

-

Configurable Laser Options: Choice of laser power and dual-laser configuration allows tailoring for speed vs detail.

-

Decent Build Volume: A 150 mm cube gives flexibility for many small-to-medium parts in one build.

-

Precision Optics: F-theta lens with small spot size (~50 m) helps deliver fine features.

-

Open Parameters & Materials: Experienced users can optimize processes or test new powders not locked down by the manufacturer.

-

Compact Footprint: The moderate machine size makes it suitable for shop-floor or lab environments without large infrastructure changes.

-

Integrated Powder Handling: Improves safety and reduces setup time compared with manual powder workflows.

-

Single-Phase Power: No need for special high-voltage infrastructure (unlike larger industrial LPBF systems).

Applications:

Manufacturing & Prototyping

-

Rapid metal prototyping of functional parts and tooling.

-

Low-volume production of bespoke components.

Aerospace & Automotive

-

Components with complex geometry and optimized weight for aerospace and automotive test pieces.

Tooling & Molding

-

Custom jigs, fixtures, core/cavity inserts, and mold tooling especially with wear-resistant steels.

Medical & Dental

-

Small part production and research into medical device manufacturing (biocompatible alloys).

Research & Education

-

University labs and R&D departments studying metal AM processes and materials.

Typical Usage Workflow

-

Design & Prep: Create 3D CAD model and prepare with slicing software (often Additive-ready formats like .STL).

-

Material & Powder: Load selected metal powder (e.g., stainless steels, aluminum, nickel alloys*). Allegheny Educational Systems

-

Machine Setup: Configure lasers, spot size, build plate, and powder system.

-

Print: Initiate LPBF build and monitor via integrated cameras/interface. Cimquest Inc.

-

Post-Processing: Remove part, depowder, heat treat, and finish as required for functionality.

General FAQs

Q1: What metals can XM200G print?

A: It supports a range including aluminum alloys, brass/bronze, copper, stainless steels (316L, 17-4 PH, etc.), superalloys (Inconel, Hastelloy), titanium Ti64, and tool steels, depending on powder availability and process development.

Q2: Do I need special facilities to install it?

A: No high-voltage requirement only standard single-phase power but proper ventilation and safety (powder and laser) are necessary.

Q3: Is it suitable for production?

A: Yes ideal for low-volume production, tooling, and prototyping; dual-laser versions boost throughput.

Q4: What resolution can I expect?

A: Layer thickness from ~20 m upwards, with precision optics supporting detailed features.

Q5: Is operator training required?

A: Yes metal LPBF involves powder handling, safety protocols, and post-processing knowledge. Experts are recommended for best results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+