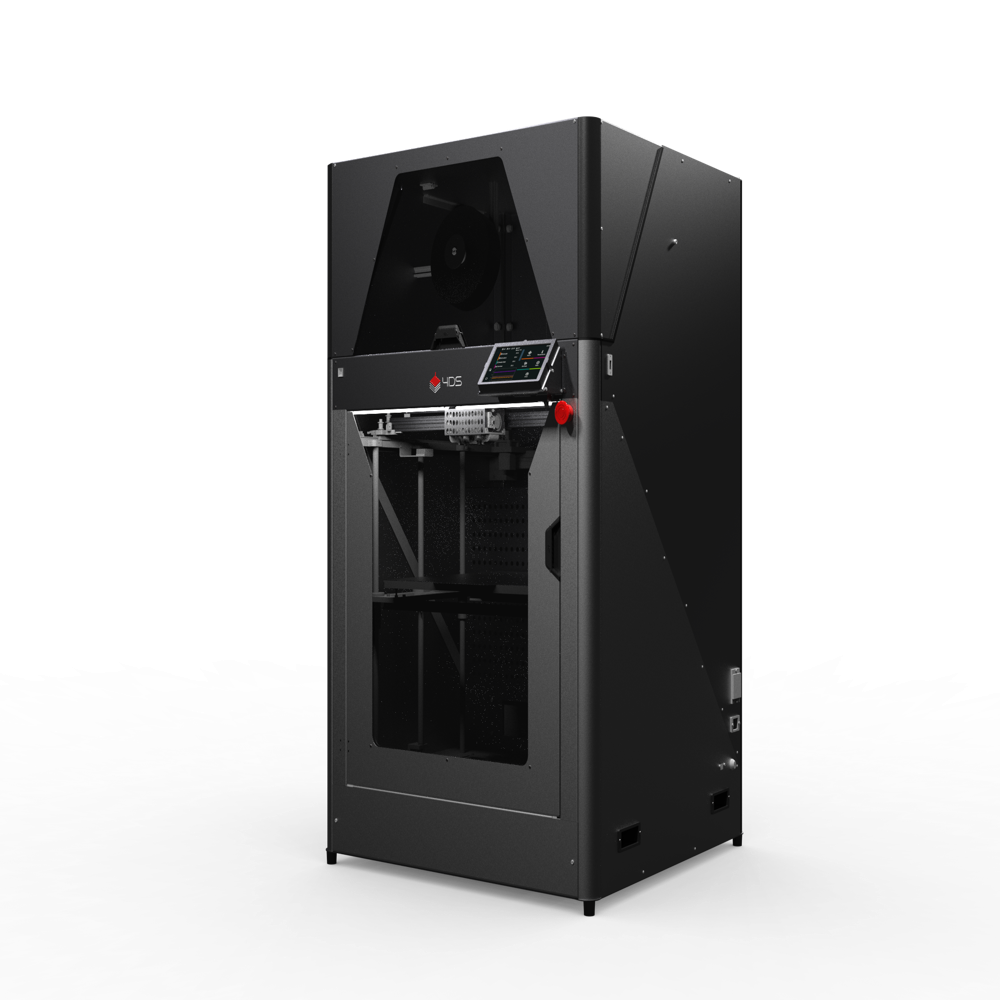

Delta WASP 2040 Clay

Product Details:

- Nozzle Diameter 1.5 mm 2 mm 3 mm

- Technology LDM

- Print Size 200 mm x h 400 mm

- Feature DM WASP Extruder 3.0 with precision screw, nozzle versatility with Luer Lock adapter, quick disassembly extruder for easy maintenance, Resurrection System to resume prints after power loss, Free Z System for restart at interruption height, parametric 3D design via WASP App, open three side access.

- Printing Speed 150 mm/s m/s

- Printer Type Liquid Deposition Modeling

- Voltage 240 Volt (v)

- Click to View more

Delta WASP 2040 Clay Price And Quantity

- 1 Number

- 600000.0 INR/Number

Delta WASP 2040 Clay Product Specifications

- DM WASP Extruder 3.0 with precision screw, nozzle versatility with Luer Lock adapter, quick disassembly extruder for easy maintenance, Resurrection System to resume prints after power loss, Free Z System for restart at interruption height, parametric 3D design via WASP App, open three side access.

- 150 mm/s m/s

- Liquid Deposition Modeling

- 200 mm x h 400 mm

- 3D Printer

- 240 Volt (v)

- Ceramic art, digital crafts, sculptures, vases, education and training, prototyping, research & development, design studios, customized design products, furniture elements, porcelain and stoneware projects.

- 1.5 mm 2 mm 3 mm

- LDM

- Porcelain, Earthenware, Gres, Refractory materials, Clays

- 40 Kilograms (kg)

- ceramic art, sculptures, vase making, digital crafts, prototyping, training, research & development, education centers, design studios, customized design products, furniture design, clay 3D printing, porcelain objects, stoneware projects, open accessible printing, resume prints after power failure, parametric 3D modeling with WASP App, Simplify3D slicing control

- 49 x 44 x 87 Centimeter (cm)

- Digital

- 1 Yr

Delta WASP 2040 Clay Trade Information

- 6 Week

Product Description

The Delta WASP 2040 Clay is a compact professional 3D printer designed for ceramic materials like clay, porcelain, and stoneware. Featuring Liquid Deposition Modeling (LDM), a 200mm dia and 400mm height build volume, precise extrusion, and easy-to-use software, it enables artists, designers, and educators to create intricate, high-quality ceramic objects with reliability and efficiency.Benefits (Pointwise)

-

Designed for Ceramics: Built to print ceramic pastes, clay, porcelain, earthenware, and similar dense materials with accuracy.

-

Resurrection System: Lets you save and resume a job after power outages or pauses, reducing material/time waste.

-

Free Z-System: Detects the exact interruption point and restarts printing from that layer.

-

Modular Extruder: Easy disassembly for cleaning and maintenance, saving downtime.

-

Professional Software Compatibility: Works with major slicers and across Windows/Mac/Linux.

-

Compact Yet Capable: Offers a large build height in a relatively small footprint.

-

Stable Frame: Aluminum and steel structure improves stability and print quality.

Typical Applications

The Delta WASP 2040 Clay is ideal for:

-

Ceramic Art & Crafts: Sculptures, decorative pieces, and personalized art.

-

Design Prototyping: Furniture elements, product prototypes, and design experimentation with ceramics.

-

Educational / Research: Art schools, universities, material science labs exploring ceramic AM.

-

Studio Production: Small-batch production of customized ceramic items.

Typical Usage Workflow

-

Prepare Ceramic Paste: Mix clay or ceramic body to suitable consistency. (Air-pressure systems help maintain smooth flow.)

-

Set Up Printer: Attach clay extruder and connect air compressor (min. ~8 bar).

-

Slice Model: Use Cura/Slic3r/Simplify3D to generate gcode from design files.

-

Start Print: Load gcode via SD card and begin printing; open frame allows mid-print interaction if needed.

-

Post-Process: Remove printed object, dry, and fire in kiln or finish according to ceramic process.

FAQs

Q1: Can I print materials other than clay?

A1: Yes porcelain, earthenware, gres, and similar ceramic mixtures are supported.

Q2: Is an air compressor needed?

A2: Yes a compressor is required to drive clay extrusion and maintain consistent feed.

Q3: Whats the maximum object height?

A3: Up to 400 mm tall within the cylindrical build volume.

Q4: Can it resume printing after a power cut?

A4: Yes thanks to the Resurrection System and Free Z-System.

Q5: What software can be used?

A5: Works with Cura, Slic3r, Simplify3D and other common slicers.

Q6: Is it beginner-friendly?

A6: It includes online training and parametric design tools to assist beginners, but ceramic printing has a learning curve (mix consistency, air pressure, etc.).

Q7: How precise are prints?

A7: Typical layer resolution up to 0.5 mm (fine for ceramics).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+